|

|

|

|

|

|

|

|

|

|

整机特性:

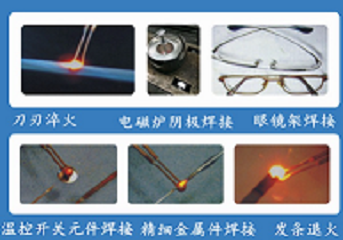

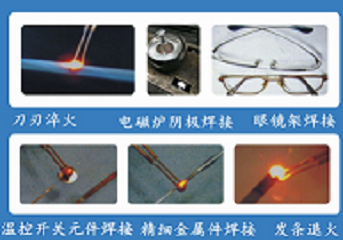

1、 TIS系列超高频感应加热设备具有频率高(频率在1-1.5MKHZ),体积小,重量轻,加热速度快,效率高,故障率低,节能等优点,比传统加热方式节能70%以上,可加热直径0.1mm 的线材;

2、 焊接牢固,美观,精致,产品表面花纹不会损伤,无明显焊疤;

3、 100%占载率,可24小时连续工作,输出功率10%-100%无极可调;

4、 主分机连接线可达3米以上,能配合自动化流水线作业,大大提高工作效率。

5、主要用于硬质合金锯齿、刀口、眼镜架零配件、珠宝首饰、钟表、鱼钩、刀具及电子行业各种极细线材、机电行业精细金属接头的焊接,微型轴心、齿轮、内孔的淬火,退火等。

Main Features:

1. TIS

Series Superhigh Frequency Induction Heating Machine have advantage

of high frequency(1-1.5MKHZ), small volume,light weight,rapid heating,high

efficiency,low fault,energy saving (saving more 70% than traditional heating

way) ect.,able to heat steel wire diameter less than Φ0.1mm;

2. Welding area quite firm and beautiful,products welded surface pattern won’t

be damaged;

3. 100% duty

cycle and 24 hours continuous work.10% -100% output power steplessly adjustable.

4.The main part and Transformer part Connecting line Up to 3 meters,more

convenient to used in automatic welding machinery and jig.

5.Welding,soldering,brazing and silver

welding for Carbide blade Saw tooth,spectacle frame parts, jewelry,watches and clocks,hook,knives

and all kinds of very fine wire in electronics industry etc;Heat treatment,

quenching, annealing for Blade, gear, fine metal joint brazing,micro axis in

mechanical and electronic industry etc.

TIS超高频感应加热设备厂家 钟表鱼钩感应加热设备厂家

¥12222 元/台

TIS超高频感应加热设备厂家 钟表鱼钩感应加热设备厂家

¥12222 元/台

龙门丝网焊专机厂家 鸟笼网架龙门丝网焊专机厂家

¥9999 元/台

龙门丝网焊专机厂家 鸟笼网架龙门丝网焊专机厂家

¥9999 元/台

TZF自动氩弧直缝焊机厂家 不锈钢圆筒直缝焊机

¥28888 元/台

TZF自动氩弧直缝焊机厂家 不锈钢圆筒直缝焊机

¥28888 元/台

TPE冲压式全自动管端扩口机厂家

¥18888 元/台

TPE冲压式全自动管端扩口机厂家

¥18888 元/台

TUN-8半自动锯条闪光对焊机厂家

¥19999 元/台

TUN-8半自动锯条闪光对焊机厂家

¥19999 元/台

全自动铜管缩口机厂家 操作简单铜管缩口机厂家

¥12000 元/台

全自动铜管缩口机厂家 操作简单铜管缩口机厂家

¥12000 元/台

TIH高频感应加热设备厂家 操作简单高频感应加热设备厂家

¥6666 元/台

TIH高频感应加热设备厂家 操作简单高频感应加热设备厂家

¥6666 元/台

TFN气动交流滚焊机厂家 横缝与纵缝滚焊机厂家

¥29999 元/台

TFN气动交流滚焊机厂家 横缝与纵缝滚焊机厂家

¥29999 元/台

TPF旋压式全自动管端喇叭口成型机厂家

¥19999 元/台

TPF旋压式全自动管端喇叭口成型机厂家

¥19999 元/台

TJK数控全自动铜管与铝管调直切断机厂家

¥28888 元/台

TJK数控全自动铜管与铝管调直切断机厂家

¥28888 元/台

TUN3铜铝管对焊机厂家直销 武汉铜铝管对焊机厂家

¥17800 元/台

TUN3铜铝管对焊机厂家直销 武汉铜铝管对焊机厂家

¥17800 元/台